The environment

Mantasoa, a place with a rich history

Historically, Mantasoa was the stronghold of Jean Laborde, an entrepreneur at heart who served the Queen of Madagascar. Not only were cannon, rifles, swords, and gunpowder made there, but also soap, tiles, paint, crockery, etc.

The landscape, made up of valleys of red earth or laterite planted with pines and eucalyptus, gives it a unique dimension. Malagasy farmers naturally knew how to make the most of the hilly terrain in the area to establish their rice fields and market gardens, and in this way produced an enchanting setting.

Due to the preserved surroundings, the waters of Lake Mantasoa are of outstanding quality, ideal for producing the best quality caviar.

Fish farming

The first sturgeon farm in Africa and the Indian Ocean

The Acipenser fish farm comprises nineteen large ponds, a hatchery, an area dedicated to pre-growout, a feed mill and a processing workshop spread over more than 8 hectares on the banks of a river fed by Lake Mantasoa upstream. It is this same lake that hosts the sturgeon when they reach 1.5 kilos in weight, holding them in about fifty giant 25m-diameter cages.

At 1,400 metres above sea level about sixty kilometres east of Antananarivo and far removed from any industries and cities, Lake Mantasoa covers 2,000 hectares to a depth of 4 - 10 metres. It is in fact a vast impluvium that collects only rainwater and is therefore protected from pollution. The fish farming ponds are fed by the waters of this lake.

Madagascar is a very large island as big as France and Belgium combined. So the climate varies considerably depending on the region. In the highlands at Mantasoa, the climate is temperate with water at a minimum of 13°C in winter and a maximum of 25°C in summer. This singularity is called a « growth optimum », i.e. the temperature range is the very best one could hope for as the fish develop.

Fish-farming performance in Madagascar is outstanding. Currently, oocytes (unfertilised eggs) measure 2.7-2.9 mm when the fish are 6 years old and weigh 9 kg on average.

The caviar yield is also impressive, averaging 15% in the farm.

Ensuring that the sturgeon develop in comfort also entails sustainable Acipenser farming by preserving the ecosystem. So the quality of the lake water was monitored even before the first farming facilities were built there. Every day, oxygen, temperature, hydrogen potential (pH) and turbidity are checked on all farming facilities. In addition to this, the weather station monitors the rainfall, air temperature, wind speed and direction on the lake. So it is possible to predict more or less difficult times during the year and to take action accordingly. Also, sturgeon growth is an essential performance indicator that is constantly watched. Care must be taken to feed them enough without overfeeding so that they do not develop more fat than caviar. Currently, the Acipenser farm has 400 tons of fish, which means 100,000 sturgeon for over 70,000 m3 of available space giving stress-free farming for the fish.

In 2019 4.2 tons of caviar were produced, falling to 3.22 tons in 2020 due to Covid-19, but production rose to around 9.2 tons in 2021.

So Acipenser opted from the start for vertical integration with very few middlemen, giving it total control of production and fish-stock traceability in order to deliver outstanding caviar.

Farmed species

A waiting game

The Acipenser sturgeon farm is divided into two facilities called the « onshore » site and the « lake » site respectively, and includes six pure species of sturgeon producing six different caviars.

For the time being, the two caviar-producing species on the farm are the Baerii, ideal for a first taste and discovering caviar, and the Ossetra, the favourite of leading Chefs.

So it has taken ten years to build the farm and import all the species we wanted, and it will take another ten years to give each species enough time to produce its caviar.

Acipenser will have reached its cruising speed by 2029.

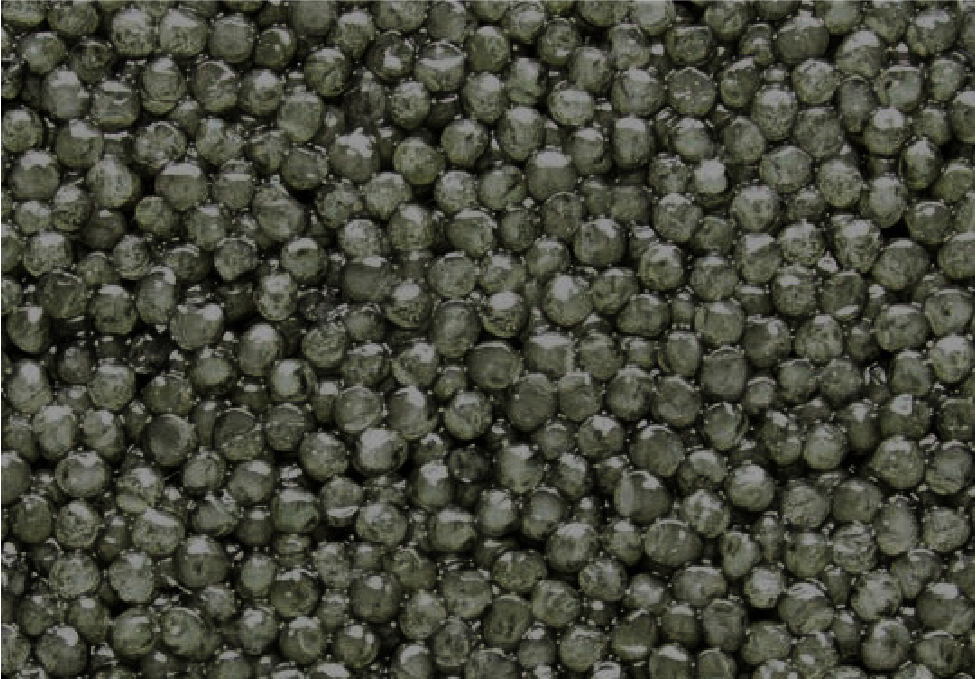

The feed mill

Feed made to measure for sturgeon

The Acipenser farm manufactures its own feed for its sturgeon in a dedicated facility called the “feed mill”. Two tons of pellets are produced on a daily basis. This practice was introduced to provide control over the entire production chain. In this way the Acipenser feed gives healthy fish, optimises their growth and produces quality caviar. Manufacturing such feed requires particular expertise because sturgeon requirements need to be matched with the technical feasibility of the machines. Sturgeon feed is composed not only of tuna meal and blue fish oil, but also non-GM plant flour such as rice bran, brewer's yeast, amino acids, soy lecithin and vitamins. No antibiotics or hormones are used, and raw materials and finished products are systematically checked, either in-house or by specialised laboratories. In order to adapt the feed to the sturgeon’s size, the feed mill produces several different grain sizes. In order to meet its environmental and corporate commitment, 80% of the raw materials are sourced from Madagascar and sourced as close as possible to the farm to reduce the carbon impact.